Services

New Build

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Refurbishment

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Upkeep

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Demolition

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

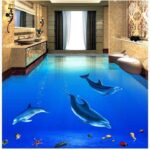

Epoxy Resin Finishes

The resin epoxy, epoxy, porcelain or liquid crystal are polymer thermoset which changes from liquid to solid state when you apply a hardener or catalyst.

Advantages of using Epoxy resin. Its characteristics as hardener, shine and transparency converts this material of exceptional qualities to one of the most floor finishes of these used applications.

The main reason for this are; high thermal resistance, waterproof, non-slip, antibacterial and flexible.

The composition of the resin allows it to support prolonged temperatures of up to 45 degrees C and

occasionally up to 70 degrees C.

It is has great resistance to corrosion and can withstand the most exposition to corrosive chemical agents.

Ideal for floors with continuous transit. Its enormous physical resistance of 65N of force per M2 makes it floor to use for garages, industrial flooring, warehouses, etc.

Very easy to install and clean at the same time thanks to its flexibility, moisturizing qualities and adherence.

Does not shrink. Different to other paints or protected surfaces it barely it contracts.

3D floor with transparent epoxy resin / Self-leveling. The absence of bad odour solvents allows the resin not to disperse when applying and it levels correctly all around.

It is very polyvalent besides being used on floors you will find it decorative items, costume jewellery, aeronautical industry and in electronics.

3D flooring consists of a vinyl with a picture to the client’s preference. The floor is prepared by leveling and smoothing the floor. The vinyl is glued and over it the Epoxy resin is given.

Due to our bad past experience with subcontractors and their lack of commitment to keeping to their word and schedules the Company took the policy decision a year and half ago that wherever possible we would avoid subcontracting. The only item that we still subcontract because it is beyond are scope is scaffolding and the company we use gives us an excellent service. Below is the list of the trades we can carry-out within our company at this moment in time:

- Plumbing

- Painting

- Aluminium structural works

- Glass installation

- Welders

- Kitchen fitters

- Plasterboard installation.

- Masons

- Tilling Thermal insulated Facade fitters.

- Plastering

- Carpenters